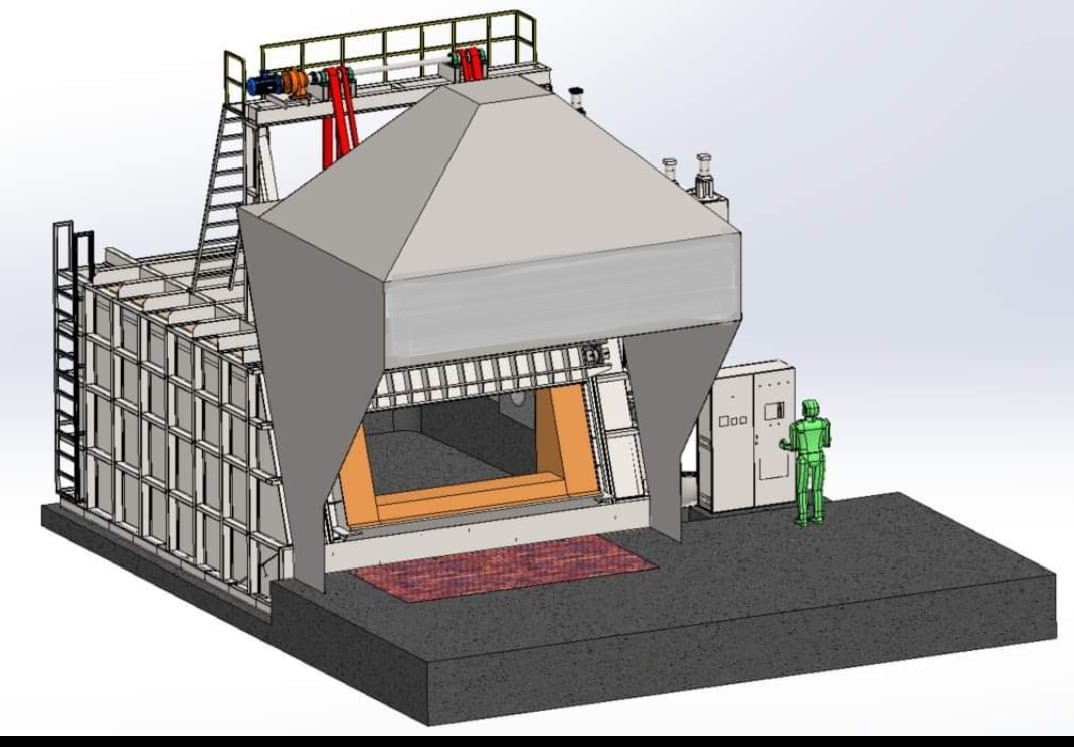

An Aluminum Furnace is an industrial heating system designed for melting and processing aluminum. It features precise temperature control to ensure efficient and uniform melting of aluminum, which is crucial for applications such as casting and alloy production. The furnace is constructed to handle high temperatures and provide consistent performance, making it essential for aluminum manufacturing processes in various industries.

Enquiry Now

An Aluminum Furnace is a specialized industrial heating system designed to melt and process aluminum with precision and efficiency. It is a crucial component in aluminum manufacturing and alloy production, ensuring that aluminum is melted uniformly and maintained at the correct temperature for various applications.

Key Features:

Precise Temperature Control: The furnace is equipped with advanced temperature control systems that maintain accurate and stable heat levels, essential for achieving optimal melting conditions and consistent quality in the final product.

High-Temperature Capability: Designed to withstand the high temperatures required for melting aluminum, the furnace can handle temperatures up to approximately 700°C (1292°F). This capability ensures effective melting and processing of aluminum and its alloys.

Efficient Melting Process: The furnace features a well-designed heating system that promotes even and efficient melting of aluminum, reducing energy consumption and minimizing heat loss.

Robust Construction: Made from heat-resistant materials and constructed to endure the harsh conditions of high-temperature operations, the furnace offers durability and long-term reliability.

Safety Features: Includes advanced safety mechanisms to protect operators and prevent accidents, such as temperature alarms, overheat protection, and secure loading and unloading systems.

Applications:

Aluminum Casting: Used in the casting process to melt aluminum and pour it into molds for producing various aluminum components and products.

Alloy Production: Essential for melting and mixing aluminum with other metals to create aluminum alloys, which are used in a wide range of industries, including automotive, aerospace, and construction.

Recycling: Plays a vital role in the recycling of aluminum, where scrap aluminum is melted and purified for reuse in manufacturing new products.

Advantages:

Consistency: Ensures uniform melting of aluminum, resulting in high-quality products and consistent performance.

Energy Efficiency: Designed to operate efficiently, minimizing energy consumption and reducing operational costs.

Durability: Built to withstand the demanding conditions of high-temperature operations, providing long-lasting performance and reliability.

Safety: Incorporates safety features to ensure a secure working environment and protect operators from potential hazards.